High-speed mass production

By hqt

Factory Mass Production at High Speed

In today’s fast-paced global market, efficiency in factory mass production is more critical than ever. High-speed manufacturing not only allows businesses to meet tight deadlines and large-scale demands but also ensures cost-effectiveness and consistency in quality. At Crystal Code Technology (Shanghai) Co.,Ltd, we leverage advanced equipment, skilled personnel, and streamlined processes to deliver superior packaging products with unparalleled speed and reliability.

Technological Advancements Driving High-Speed Production

The cornerstone of efficient mass production lies in state-of-the-art machinery and technology. High-speed production lines equipped with automated systems ensure that large quantities of products are manufactured with precision and minimal downtime. Technologies such as:

- Robotic automation: Reduces manual intervention and increases output consistency.

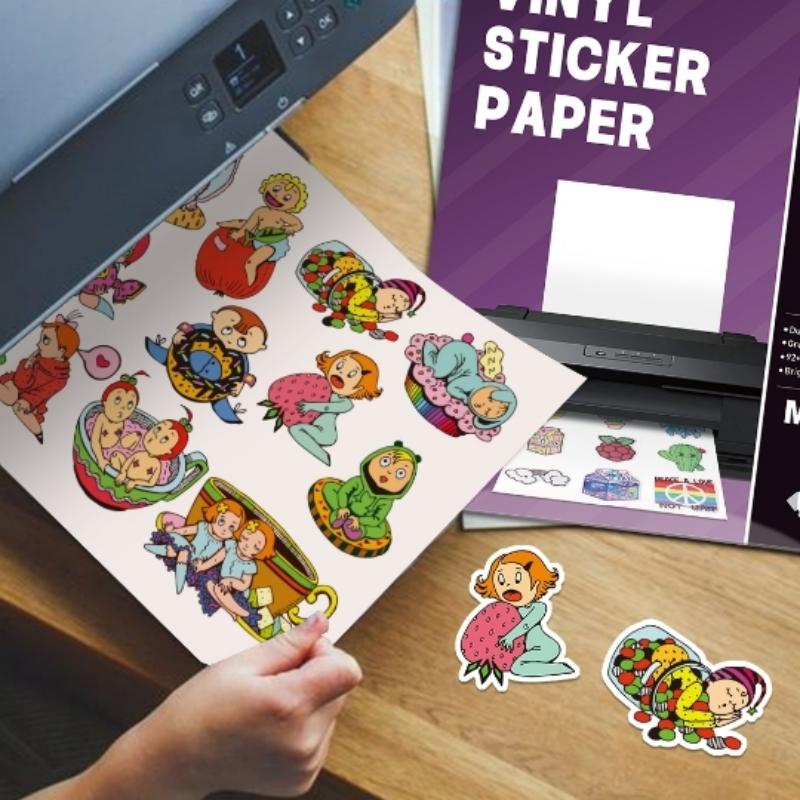

- Digital printing solutions: Enable rapid customization and high-quality results.

- Efficient material handling systems: Streamline the movement of raw materials and finished goods.

These innovations not only boost production speed but also minimize waste and operational costs.

Streamlined Processes for Maximum Efficiency

To achieve high-speed mass production, every step of the manufacturing process must be meticulously planned and optimized. This includes:

- Pre-production planning: Ensuring that all design requirements and raw materials are ready before production begins.

- Real-time monitoring: Using advanced tracking systems to oversee production and quickly resolve issues.

- Quality control integration: Embedding inspection checkpoints throughout the process to maintain product standards without slowing down the line.

By fine-tuning these processes, we achieve a seamless flow of production, even at high volumes.

Balancing Speed and Quality

While speed is essential, quality remains a top priority. At Crystal Code Tec, we employ rigorous quality assurance protocols to ensure that every product meets customer specifications. Advanced testing equipment and skilled technicians work together to maintain consistency, ensuring that high-speed production never compromises product reliability.

Benefits of High-Speed Mass Production

The advantages of high-speed manufacturing extend beyond faster turnaround times. They include:

- Cost savings: Increased efficiency reduces labor and overhead costs.

- Scalability: Ability to handle large orders without compromising delivery timelines.

- Customer satisfaction: Meeting tight deadlines and maintaining quality builds trust and long-term partnerships.

Meeting Diverse Industry Demands

Our expertise in high-speed mass production allows us to serve a wide range of industries, including food, medical, electronics, and cosmetics. Whether producing adhesive labels, food-grade packaging bags, or custom-designed paper boxes, our high-speed production capabilities ensure that we meet the unique needs of every client.